Efficient production processes require the economical use of raw materials. The material should be used as sparingly as possible without falling short of the defined requirements. Even a saving of just one percent can bring considerable cost benefits: With an average mass throughput of one ton per hour, 8000 production hours per year and a material value of EUR 1500 per ton, EUR 120,000 can be saved annually.

Material can be used more efficiently by reducing wall thicknesses, for example. However, care must be taken to ensure that the minimum layer thickness is not undercut in order to avoid rejects. Inspection systems that are directly integrated into the production process are required for monitoring.

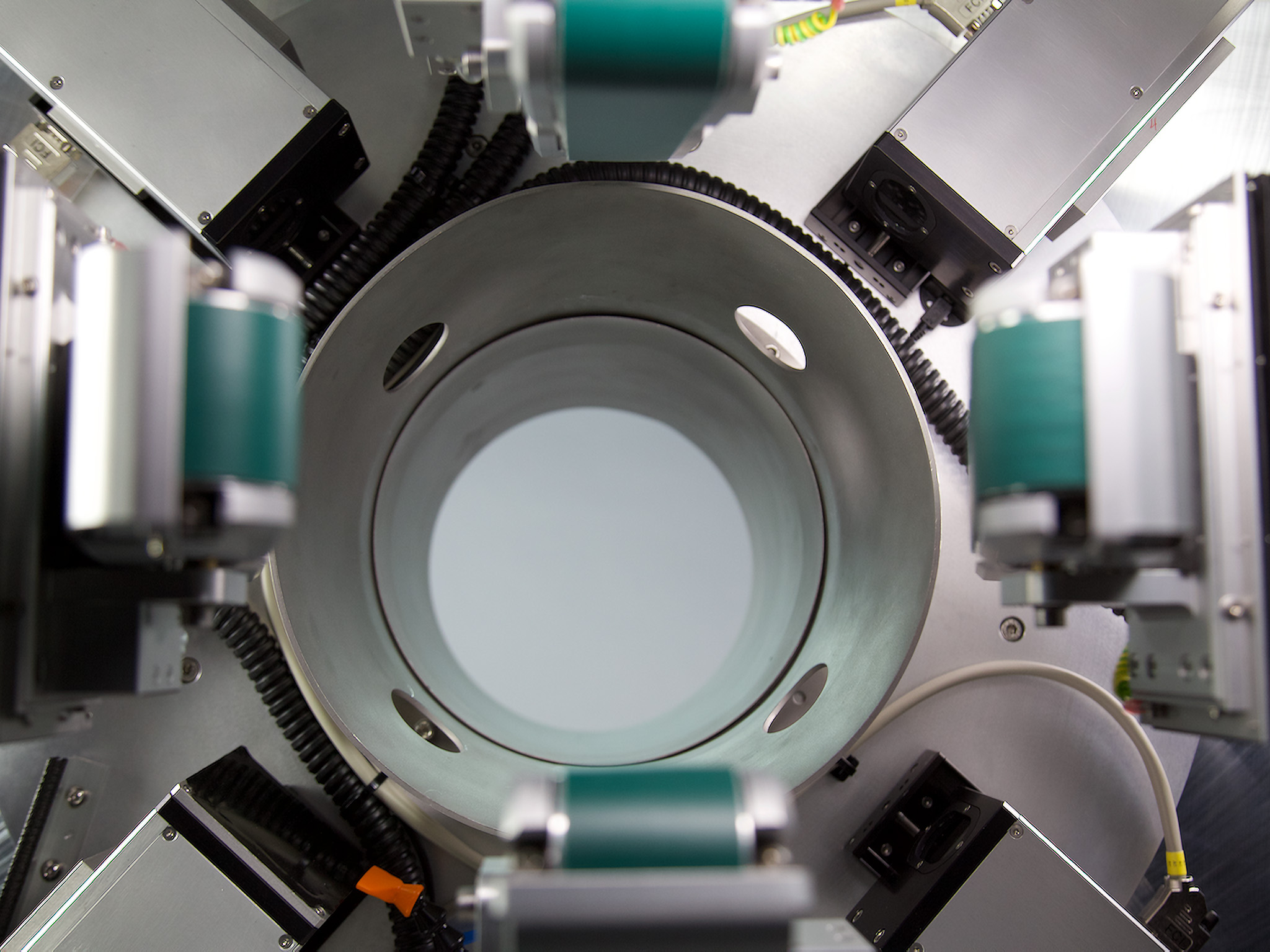

The quality of plastic pipes and hoses is determined and documented by an inline inspection system early in the process:

- Diameter

- Wall Thickness

- Layer Structure

- Ovality

- Sagging (sagging of the melt during solidification if viscosity is too high)